Content

All issues / Volume 19 (2025) / Issue 2 (February)

This is an editorial article. It has no abstract.

Improving UV-C stability in polypropylene through synergistic phenolic or hydroxylamine-based additives with UV absorbers

Marcos Vinícius Basaglia, Jessica Caroline Ferreira Gimenez, Manoel Gustavo Petrucelli Homem, Sandra Andrea Cruz, Lucas Henrique Staffa, Sílvia Helena Prado Bettini

Vol. 19., No.2., Pages 124-139, 2025

DOI: 10.3144/expresspolymlett.2025.10

Vol. 19., No.2., Pages 124-139, 2025

DOI: 10.3144/expresspolymlett.2025.10

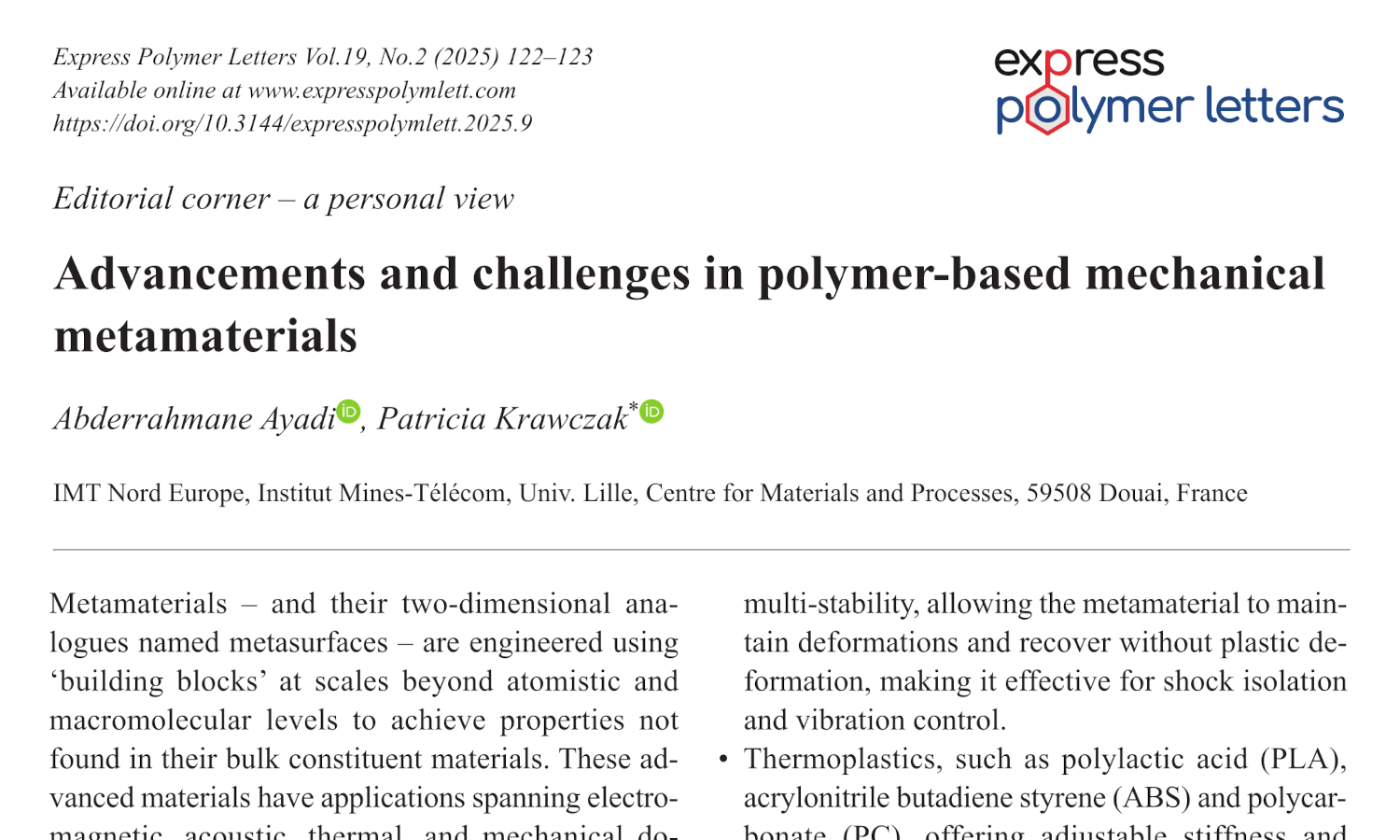

UV-C radiation (200–280 nm) is recognized for its effectiveness in disinfection, but it also induces degradation in polymeric materials such as polypropylene (PP), reducing their service life. Stabilizing additives are a viable approach to mitigating or delaying the degradation process. However, the chemical groups within these additives may adversely affect stabilization under UV-C exposure due to their potential to absorb the radiation. This study investigates the degradation of PP under UV-C radiation and evaluates the performance of stabilization systems containing phenolic antioxidants (Irganox 1010), hydroxylamine (Irgastab FS 042), and UV absorbers (Tinuvin 1577). PP films were exposed to UV-C radiation for 24, 48, and 96 h, corresponding to doses of 1000, 2000, and 4000 J/cm2. Degradation was assessed using size exclusion chromatography (SEC), parallel plate rheometry, infrared spectroscopy (FTIR), static water contact angle, and mechanical testing. The independent use of antioxidants or UV absorbers resulted in reduced carbonyl group formation relative to neat PP, but these were insufficient to prevent PP brittleness after 96 h of exposure. In contrast, the combined use of hydroxylamine or phenolic additives with UV absorbers effectively preserved PP ductility, allowing deformations exceeding 300% without fractures, indicating a synergistic effect.

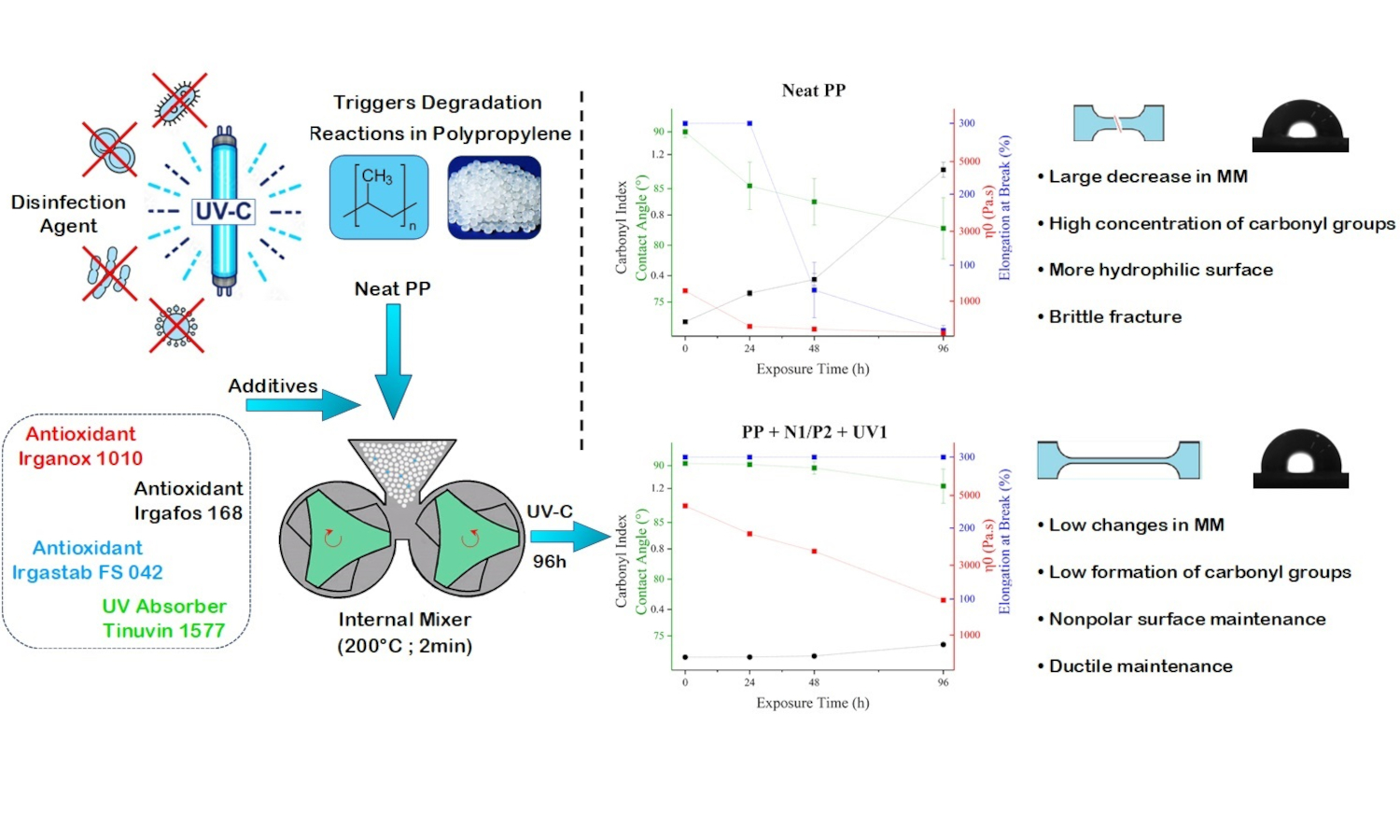

Fibre-reinforced thermoset matrix polymer composites are gaining popularity in structural applications with strict quality requirements. However, their failure process, which is hard to predict and often catastrophic, mostly occurring at random locations, might be unfavourable in these areas. To ensure the further spread of composites and increase their reliability, their failure processes have to be influenced and controlled. This article gives an overview of different methods for influencing the damage process and failure behaviour of fibre-reinforced composite materials with thermoset polymer matrix. We describe the different methods, which can either control the failure in terms of location or mode or modify the failure behaviour, mostly by increasing toughness or achieving pseudo-ductile behaviour with a more gradual failure process. These methods can also simplify structural health monitoring, which has great importance in several applications of composite materials. The article focuses on the methods that enable the manipulation of the failure process by creating artificial damage or modifying the reinforcement, the matrix, the fibre-matrix interface, or the interlayer.

Poly(methyl methacrylate) blends with quaternized polyethyleneimine: A study of morphology, optical, thermal and mechanical properties

Rafael Affonso Netto, Guilherme Ribeiro de Carvalho, Lucas Henrique Staffa, Liliane Maria Ferrareso Lona

Vol. 19., No.2., Pages 161-175, 2025

DOI: 10.3144/expresspolymlett.2025.12

Vol. 19., No.2., Pages 161-175, 2025

DOI: 10.3144/expresspolymlett.2025.12

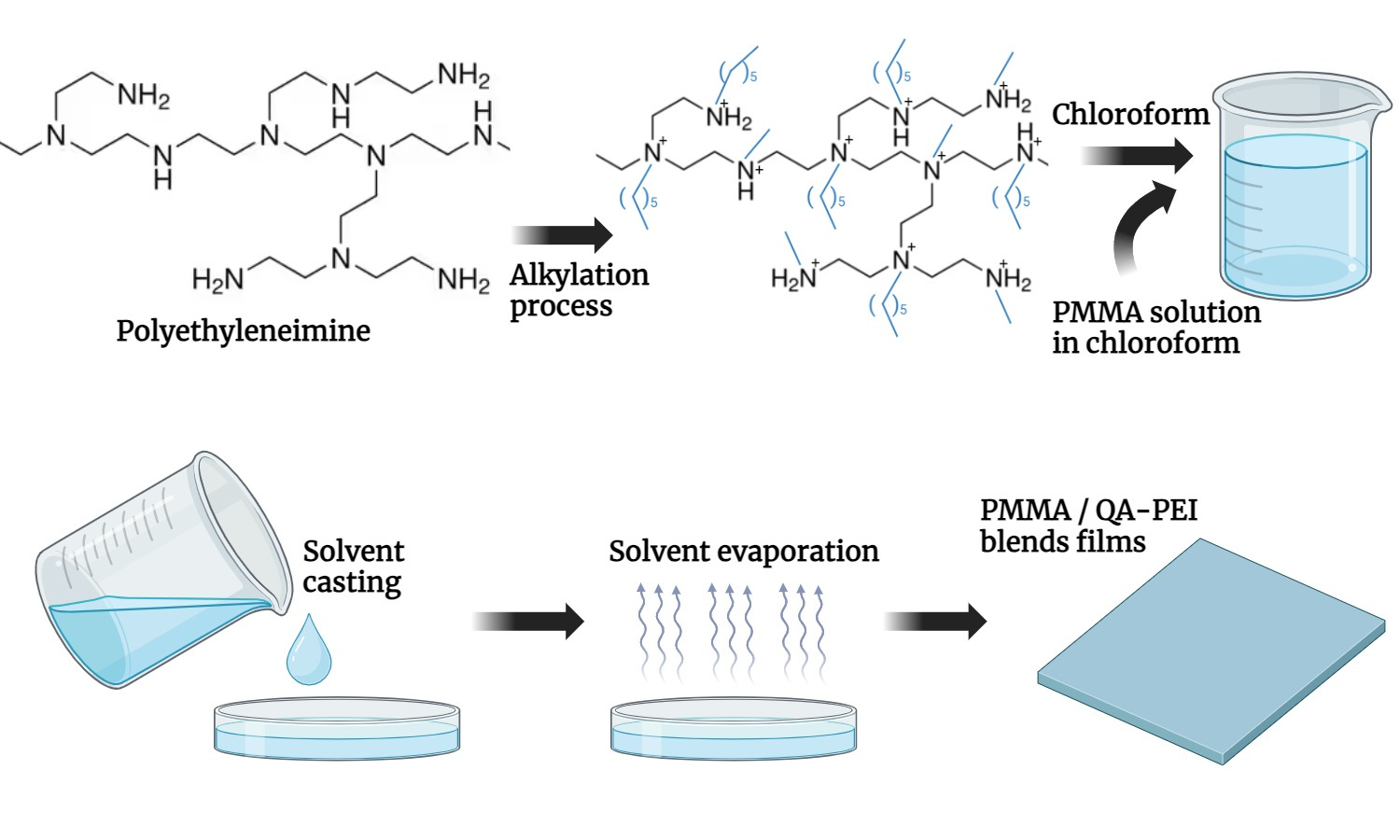

This study aimed first to promote the alkylation of polyethyleneimine (PEI), developing its alkylated (quaternary) form (QA-PEI) by inserting alkyl groups into amine groups. Subsequently, polymer blends with poly(methyl methacrylate) (PMMA) were prepared via solvent casting, and finally, the physicochemical, optical, and mechanical behavior of the resulting PMMA/QA-PEI were assessed. Elemental analyses, Fourier-transform infrared spectroscopy (FT-IR), and hydrogen nuclear magnetic resonance spectroscopy (1H-NMR) confirmed that the PEI alkylation successfully converted the amine groups into quaternary ammonium groups. When added to PMMA, QA-PEI altered its coloration, making it yellow. In addition, higher contents of QA-PEI hindered PMMA transmittance and increased its opacity due to the larger QA-PEI domains. Scanning electron microscopy (SEM) images showed that PMMA and QA-PEI formed a phase-separated system, establishing a droplet-matrix morphology. The thermal and mechanical behavior showed some compatibility between PMMA and QA-PEI as thermal resistance slightly improved and PMMA glass transition temperature (Tg) decreased. The tensile strength was also improved in the PMMA/QA-PEI blends without significant change in strain at break and tensile modulus.

A novel photocatalytic sheath/core bicomponent fibre for severe acute respiratory syndrome coronavirus inactivation

Widtawad Reantong, Siriluk Chiarakorn, Pornsawan Leangwutwong, Akanitt Jittmittraphap, Nanjaporn Roungpaisan, Natee Srisawat

Vol. 19., No.2., Pages 176-191, 2025

DOI: 10.3144/expresspolymlett.2025.13

Vol. 19., No.2., Pages 176-191, 2025

DOI: 10.3144/expresspolymlett.2025.13

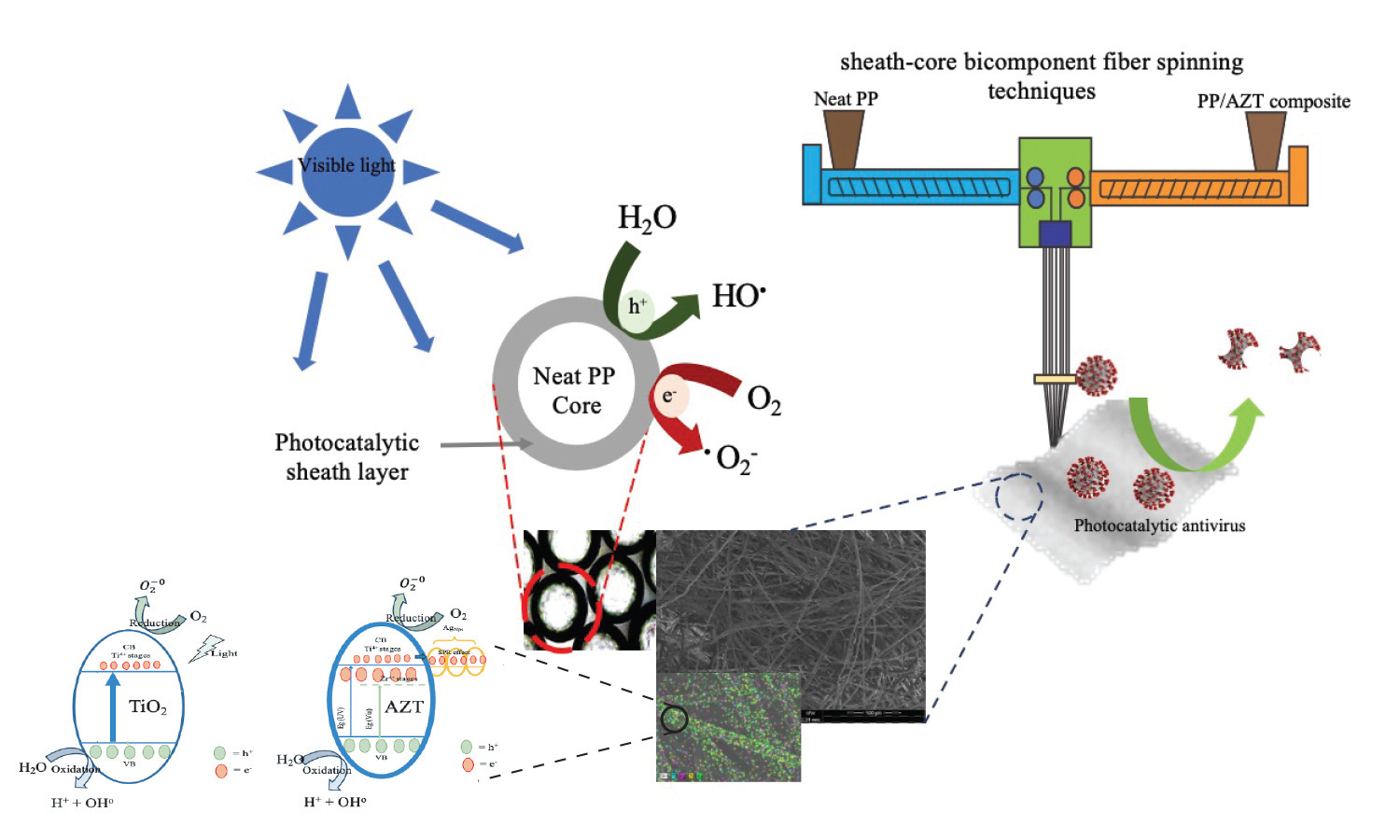

The coronavirus disease of 2019 (COVID-19) has become a global pandemic, leading to severe health issues such as pneumonia, organ failure, and death. Face masks made of non-woven textiles have been widely used to protect against SARS-CoV-2, but concerns arose regarding the potential infection from contaminated masks. To address this, titanium dioxide, a photocatalyst, shows promise in antimicrobial applications, including virus inhibition. This study explores the development of a sheath-core bicomponent fibre with a polypropylene core and a sheath containing an Ag and Zr co-doped TiO2 photocatalyst (AZT). Zr-Ag-TiO2 The fibres were produced using a double-extrusion spinning system, and the effects of the sheath-core ratio (50:50 and 80:20 w/w) and AZT content (1–3 wt%) on mechanical and antiviral properties were analysed. The fibres demonstrated improved mechanical strength and thermal stability, with the highest anti-SARS-CoV-2 activity (99.91%) observed in fibres with 2 wt% AZT at a 50:50 ratio after 30 min of fluorescent irradiation.

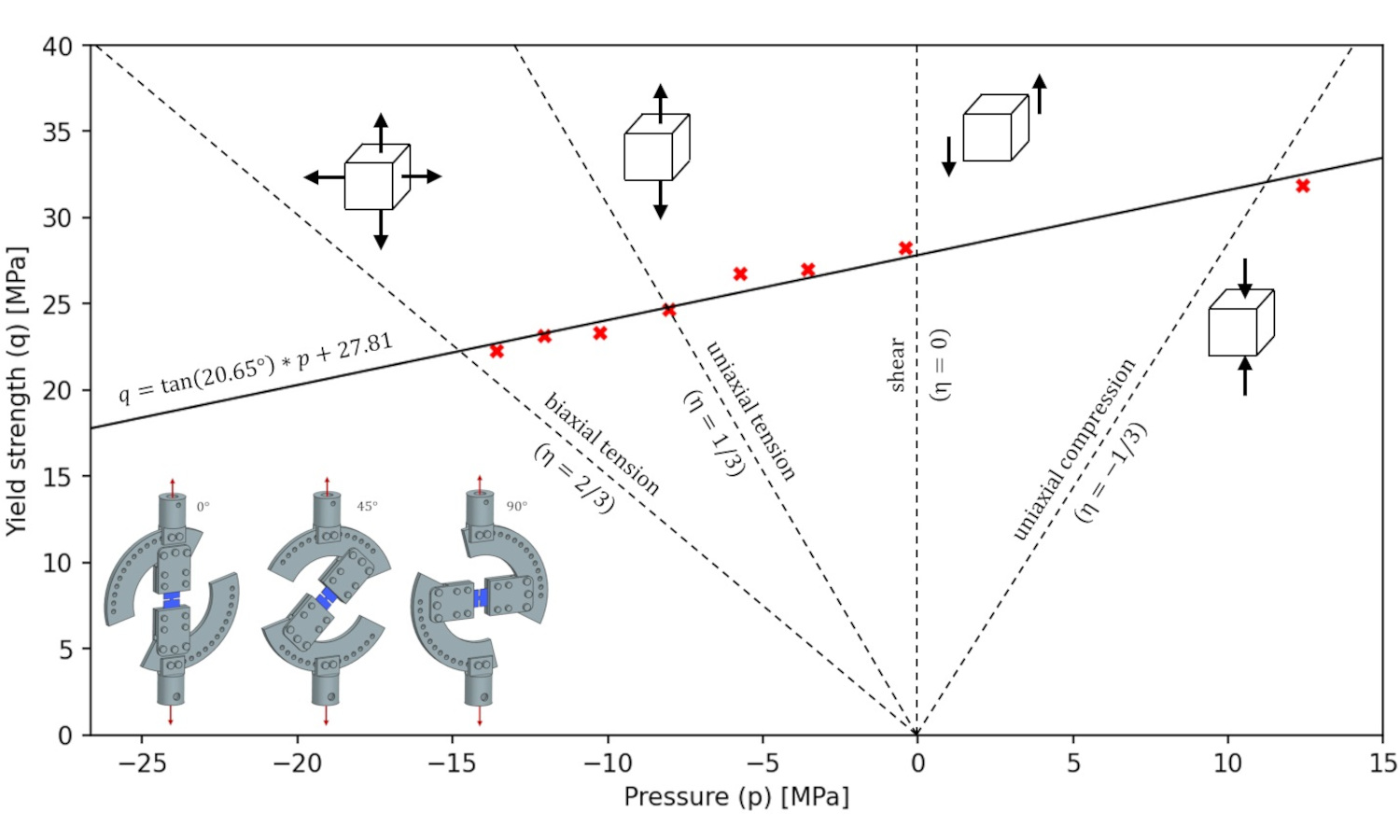

This study focuses on calibrating the linear Drucker-Prager yield criterion for polypropylene under multiaxial loading conditions, using the Arcana fixture to achieve a wide range of triaxiality states. The Drucker-Prager criterion has been adapted for polymers, composites, and metals due to its ability to reflect the influence of hydrostatic pressure on yield stress. This study employs the Arcana fixture, which allows for testing flat plate samples under various angles, thereby simulating different stress states from pure shear to biaxial tension. Additionally, uniaxial compression tests were conducted to extend the range of triaxiality. The material used in this study is Sabic 83MF10, a polypropylene polymer. Samples were prepared by injection moulding and cut to specific dimensions. Tests were performed using a universal testing machine with the Arcana fixture, and the results were analysed to determine the yield strength, pressure, and triaxiality for each sample. The results showed a linear relationship between von Mises stress and hydrostatic pressure, with a friction angle (β) of 20.65° and material cohesion (d) of 27.81. The numerical simulations in Abaqus confirmed the validity of the Drucker- Prager model, accurately reflecting the moment of yielding for the tested samples.

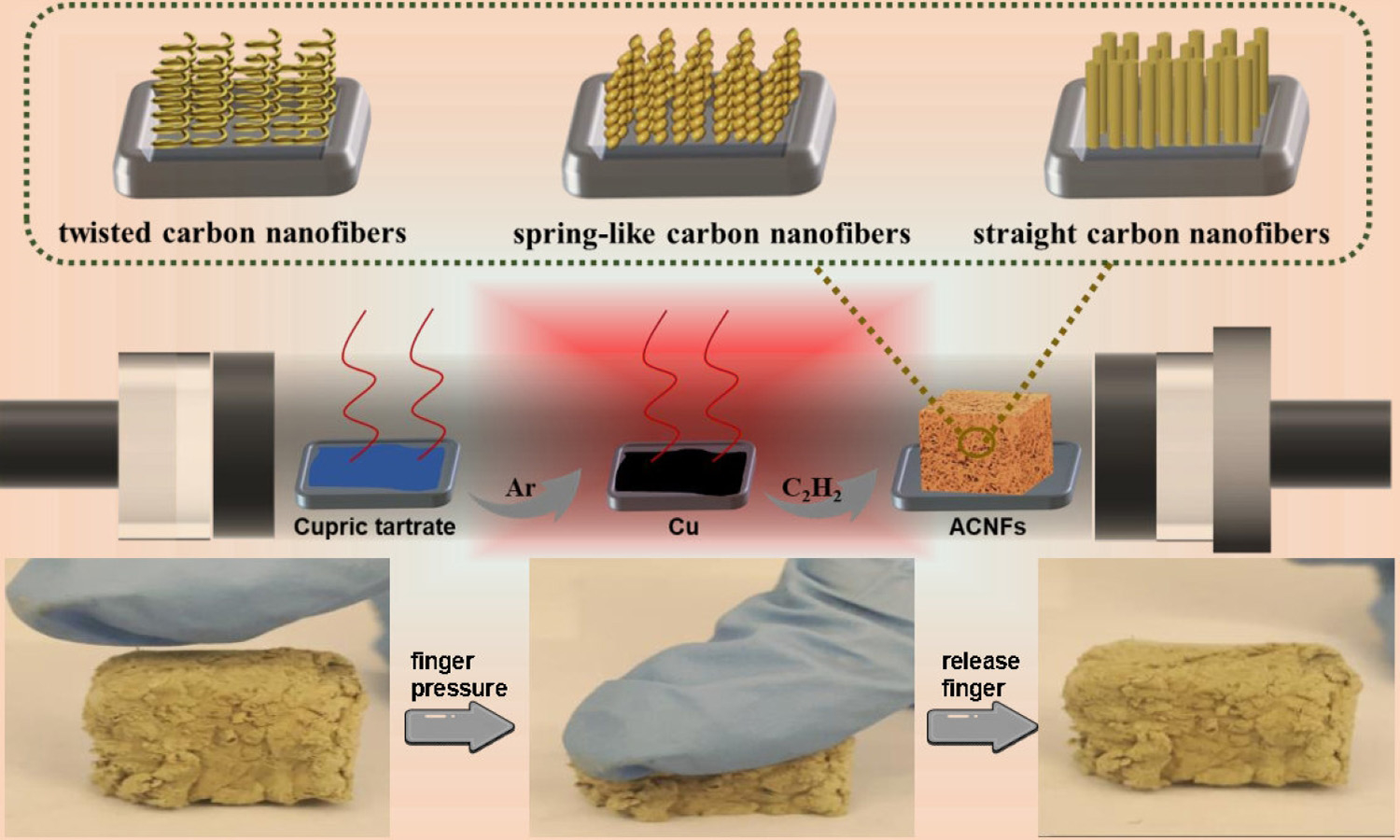

In this work, a foam composed of helical carbon nanofiber arrays was successfully synthesized via chemical vapor deposition. By controlling synthesis parameters including the synthesising temperature and gas flow rate, carbon nanofibers with straight, kinked, and spring-like morphologies were obtained. Adjusting the precursor feed led to the formation of foams with well-ordered carbon nanofiber structures. The nanofibers exhibit diameters ranging from 98 to 175 nm and lengths extending to the centimetre scale. Experimental results confirm that these fibers are organic carbon nanofibers, attributed to low-temperature catalytic synthesis. Structural characterization reveals that the catalyst assumes a regular polyhedral shape and becomes embedded within the fibers, which symmetrically grow from both faces of the catalyst. Structural analysis indicate that the carbon nanofibers are hollow, multi-walled structures with numerous defects. The resulting foam demonstrates porous, along with excellent elasticity and high mechanical strength.

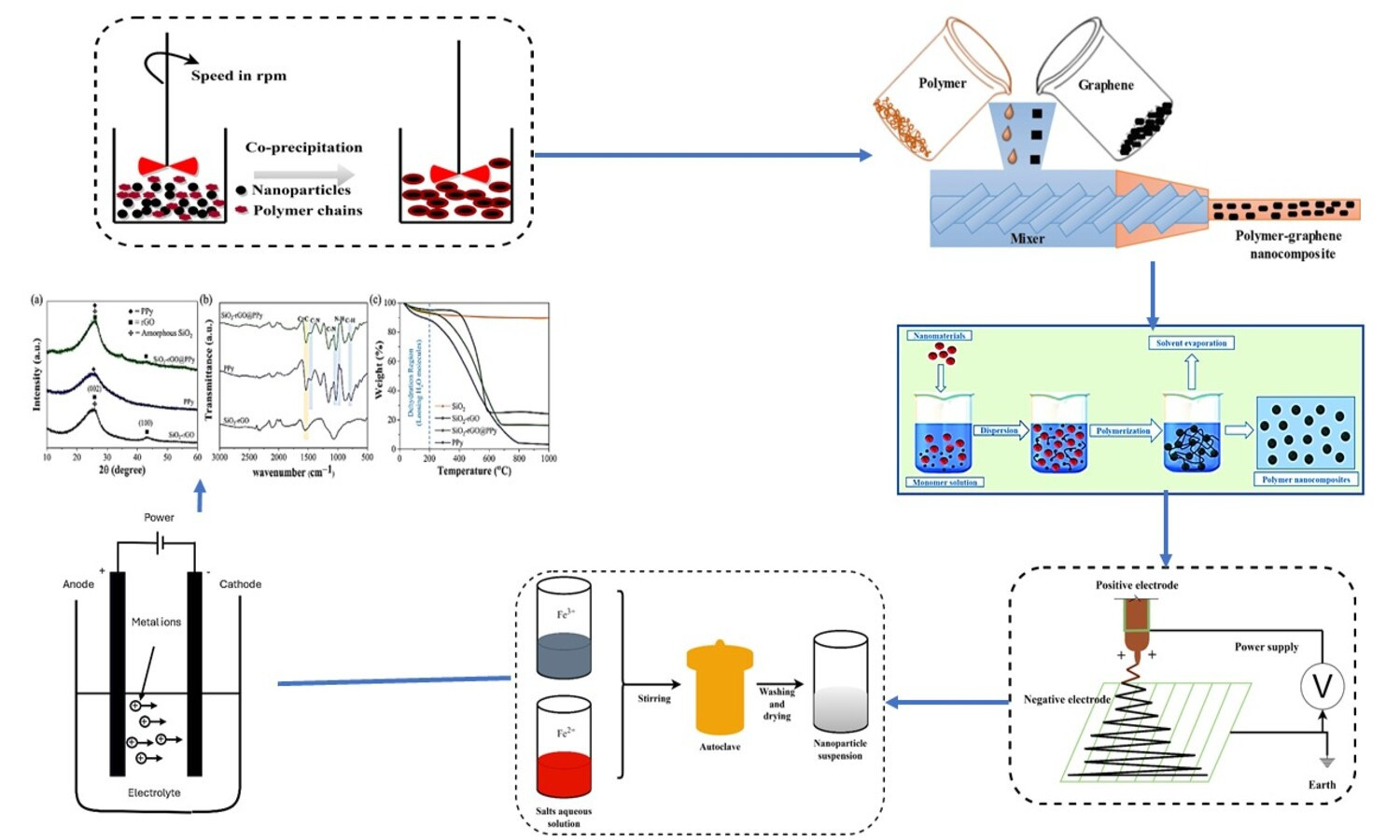

Selection criteria of polymer nanocomposites for electrical energy storage applications: A concise review

Mathew Olurotimi Adeoti, Tamba Jamiru, Taoreed Adesola Adegbola, Ibrahim Suleiman, Mohammed Abdullahi, Basiru Philip Aramide

Vol. 19., No.2., Pages 208-229, 2025

DOI: 10.3144/expresspolymlett.2025.16

Vol. 19., No.2., Pages 208-229, 2025

DOI: 10.3144/expresspolymlett.2025.16

Polymer nanocomposites are drawing considerable interest in electrical energy storage research owing to their distinctive characteristics and promising roles in various devices, such as batteries, supercapacitors, and fuel cells. This review examines the selection criteria of polymer nanocomposites for electrical energy storage applications and the current advancements in developing and producing polymer nanocomposites specifically tailored for electrical energy storage applications. Key topics covered include the selection of polymer matrices, choice of nanofillers, fabrication techniques, characterization methods, and performance evaluation of the resulting nanocomposites. The impact of nanofiller dispersion, interface engineering, and morphology control on electrical storage properties is emphasized. Proper dispersion enhances uniformity and interfacial interactions, improving electrical, mechanical, and thermal properties. Interface engineering boosts polymer-nanofiller compatibility, while morphology control optimizes nanofiller structure and arrangement for better storage efficiency. Emerging trends, challenges, and future research directions are also discussed, providing insights for developing advanced polymer nanocomposites with improved electrical energy storage capabilities.